Drinking Water Washing Filling Capping Machine Automatic Bottle Filling Machine Desktop

The Drinking Water Washing Filling Capping Machine - Automatic Bottle Filling Machine (Desktop) is a compact, efficient, and versatile solution designed for small to medium-scale production of bottled drinking water. Below is a detailed overview of its features, applications, benefits, and technical specifications.

Key Features:

Compact Desktop Design:

金彩汇Space-saving footprint, ideal for small production facilities, laboratories, or startups.

金彩汇Easy to install and operate on a tabletop or counter.

Fully Automatic Operation:

3-in-1 Process: Combines washing, filling, and capping in one integrated machine.

Nozzle Count: Typically 2-4 nozzles (customizable for higher speeds).

High Accuracy and Efficiency:

Precise Filling: Servo motor control ensures accurate volume dispensing (±0.5% error).

Speed: Up to 100-200 bottles per hour (depending on bottle size and nozzle count).

Hygienic Design:

Stainless Steel Construction (304/316L) for durability and food safety.

CIP (Clean-In-Place) Function: Automated cleaning system for sanitizing the machine without disassembly.

Drip-Free Nozzles金彩汇: Prevents product leakage and contamination.

Versatile Compatibility:

Suitable for PET bottles, glass bottles, and HDPE containers.

金彩汇Accommodates various bottle sizes (e.g., 250ml to 2000ml) with quick changeovers.

Smart Control System:

PLC-Based Automation with a touchscreen HMI for easy operation and monitoring.

Recipe Management: Store multiple filling parameters for different products and bottle sizes.

Safety Features金彩汇: Emergency stop buttons, interlock systems, and safety guards.

Energy-Efficient:

金彩汇Low power consumption and quiet operation.

金彩汇Pneumatically or electrically driven (depending on configuration).

Modular and Customizable:

Can be integrated with additional equipment like conveyors, labelers, or shrink sleevers.

Optional add-ons: Nitrogen dosing, date coding, and barcode scanning.

Applications:

Bottled Drinking Water金彩汇: Purified water, mineral water, spring water, and flavored water.

Beverages: Juices, teas, energy drinks, and soft drinks.

Liquids: Oils, sauces, syrups, and cosmetic liquids.

Pharmaceuticals金彩汇: Oral liquids, syrups, and specialty medications.

Small-Scale Production金彩汇: Startups, cottage industries, and labs.

Benefits:

Efficiency:

Fully automated washing, filling, and capping reduce labor costs and production time.

金彩汇High-speed operation meets small to medium production demands.

Hygiene:

Stainless steel construction and CIP functionality ensure a clean, contaminant-free environment.

金彩汇Drip-free nozzles minimize product waste and cross-contamination.

Flexibility:

Quick changeover between bottle sizes and products using recipe management.

金彩汇Compact design allows for easy integration into existing workflows.

Cost-Effectiveness:

Low maintenance and durable construction minimize long-term operating expenses.

Energy-efficient operation reduces utility costs.

User-Friendly:

Touchscreen HMI and intuitive controls require minimal training.

Safety features protect operators and prevent accidents.

Technical Specifications (Example):

Filling Speed: 100-200 bottles/hour (depending on nozzle count and bottle size).

Nozzle Count金彩汇: 2-4 (customizable).

Filling Accuracy: ±0.5% (weight-based or volumetric).

Materials金彩汇: 304/316L stainless steel, food-grade polymers, and PTFE seals.

Power Source: Electric (220V/50Hz or 110V/60Hz) with optional pneumatic assistance.

Control System金彩汇: PLC with touchscreen HMI (Siemens, Omron, or similar).

Dimensions: Compact footprint (e.g., 1000mm x 600mm x 1500mm).

Weight: ~300 kg (depending on configuration).

Bottle Compatibility: PET, glass, and HDPE bottles (250ml to 2000ml).

Optional Add-Ons:

Conveyor System: Automated transport of bottles for continuous operation.

Labeling Machine: Automatic application of front/back labels or wraparound labels.

Nitrogen Dosing: For preserving product freshness by purging oxygen from containers.

Data Logging: USB or Ethernet connectivity for recording fill data and integration with MES/ERP systems.

RFID/Barcode Scanners金彩汇: For automatic container recognition and tracking.

Temperature Control: Heating or cooling modules for temperature-sensitive products.

Conclusion:

The Drinking Water Washing Filling Capping Machine - Automatic Bottle Filling Machine (Desktop)金彩汇 is an ideal solution for small to medium-scale production of bottled water and other liquids. Its compact design, fully automated operation, and hygienic features make it a reliable and efficient choice for startups, laboratories, and cottage industries. Whether you’re producing bottled water, beverages, or pharmaceuticals, this machine ensures consistent quality, reduces labor costs, and meets the highest hygiene standards.

Immediate Order:

Website: http://zonghengdazong.com/product/drumfillingmachines-en.html

Alibaba:

金彩汇China Manufacturing Co Ltd.:

-

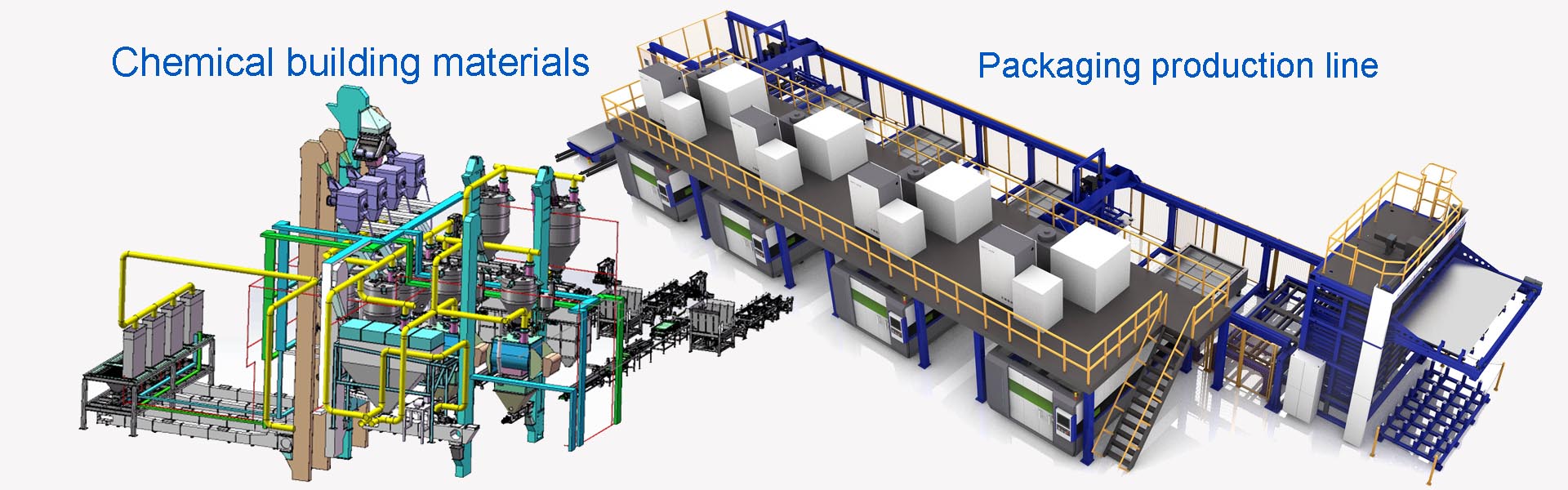

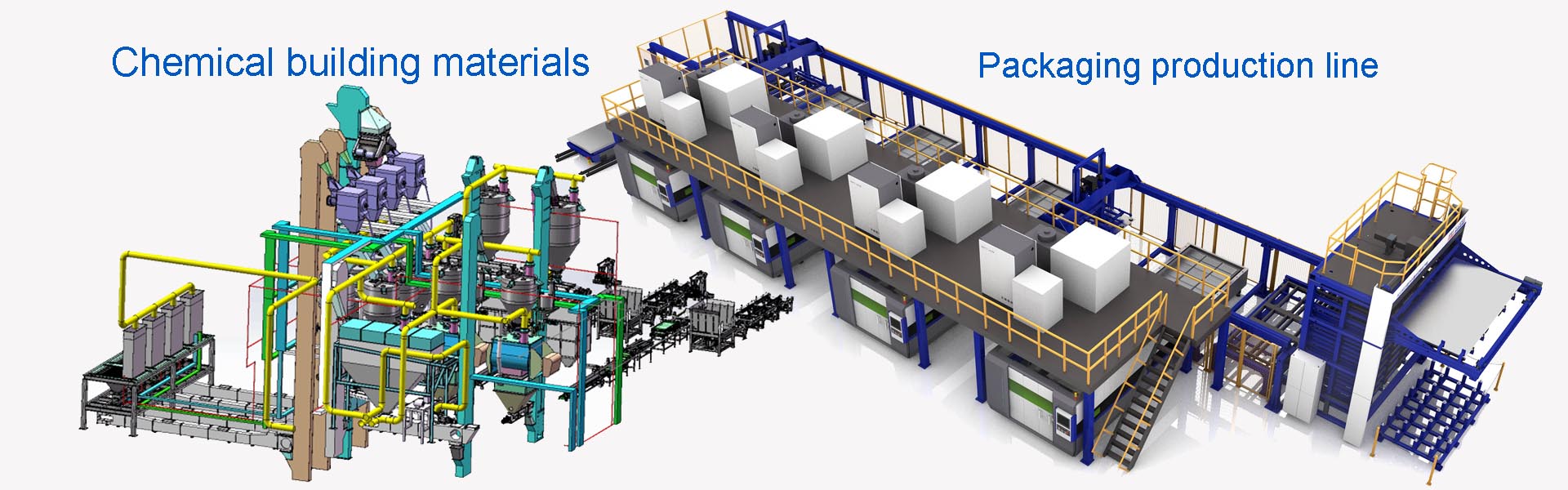

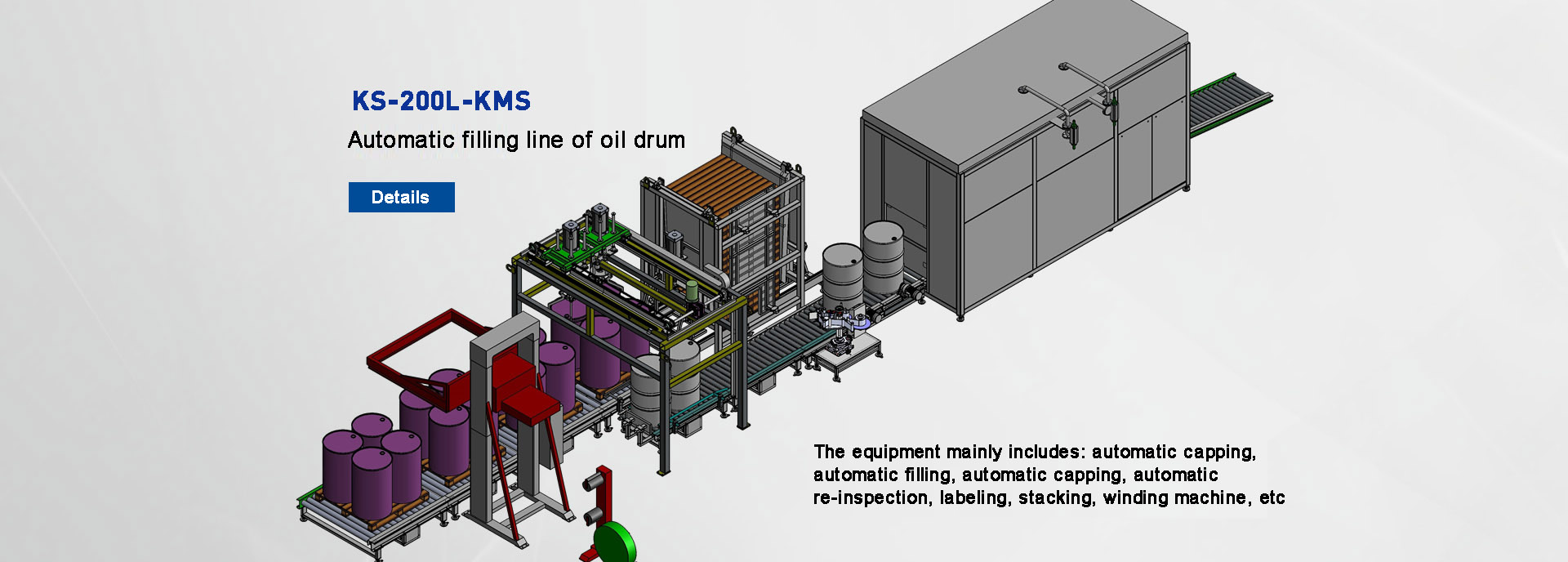

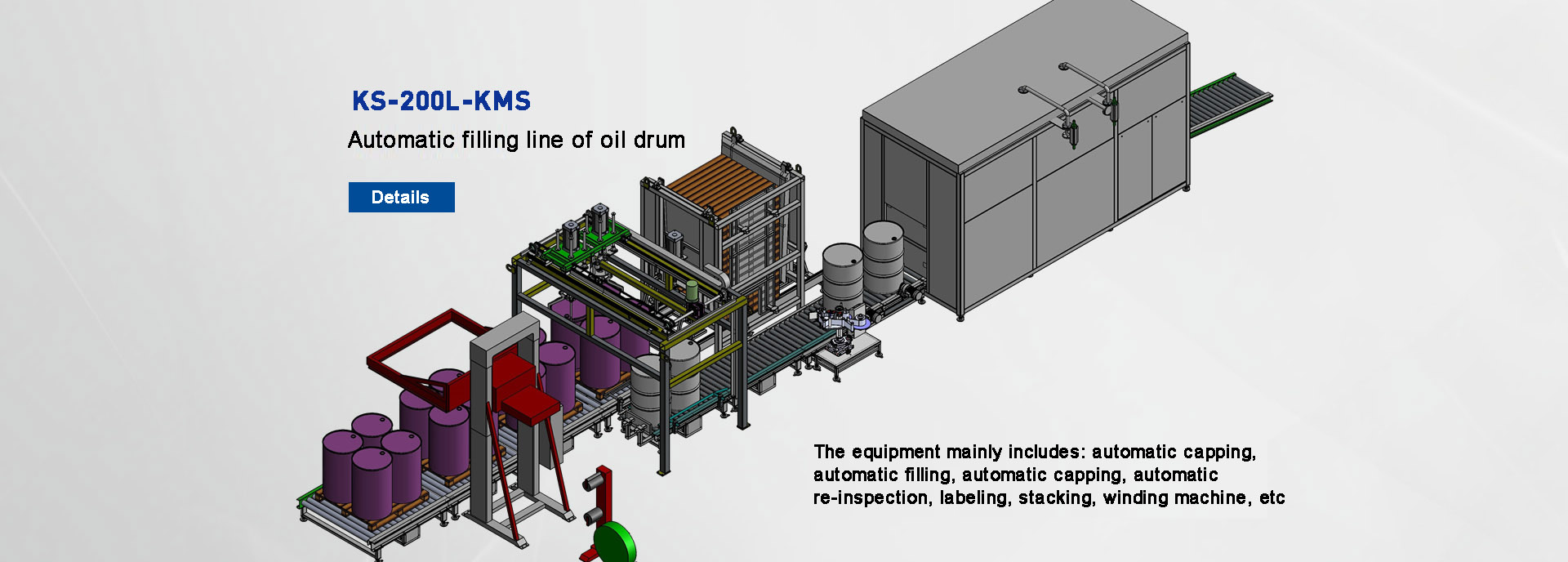

Fully Automatic Liquid Weighing Filling Machine for 220L[2025-05-17]

-

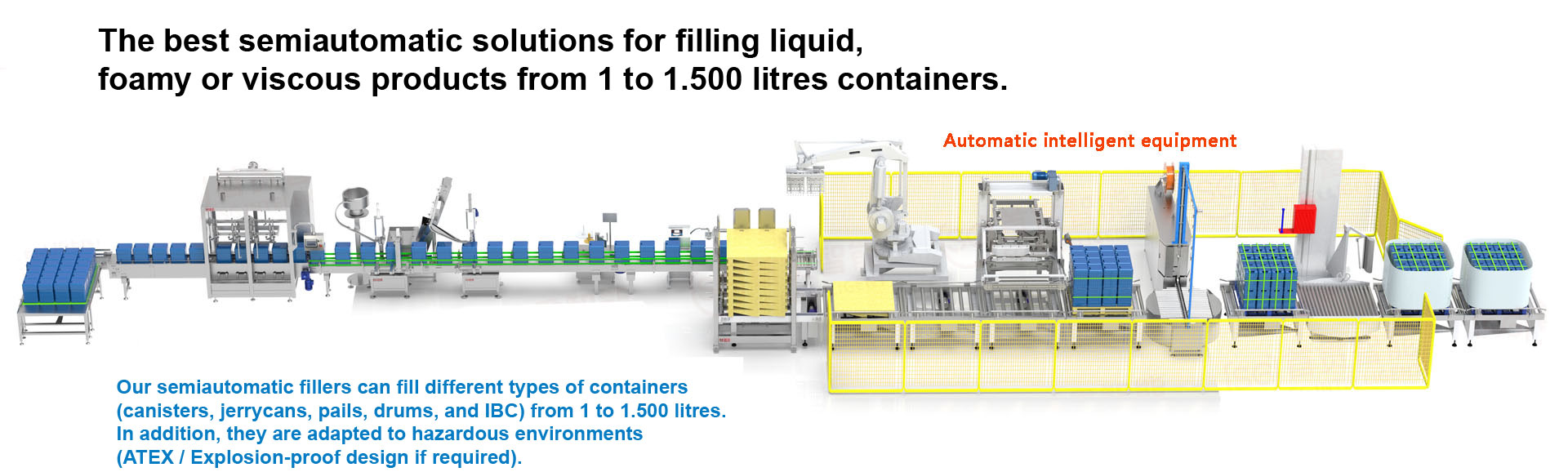

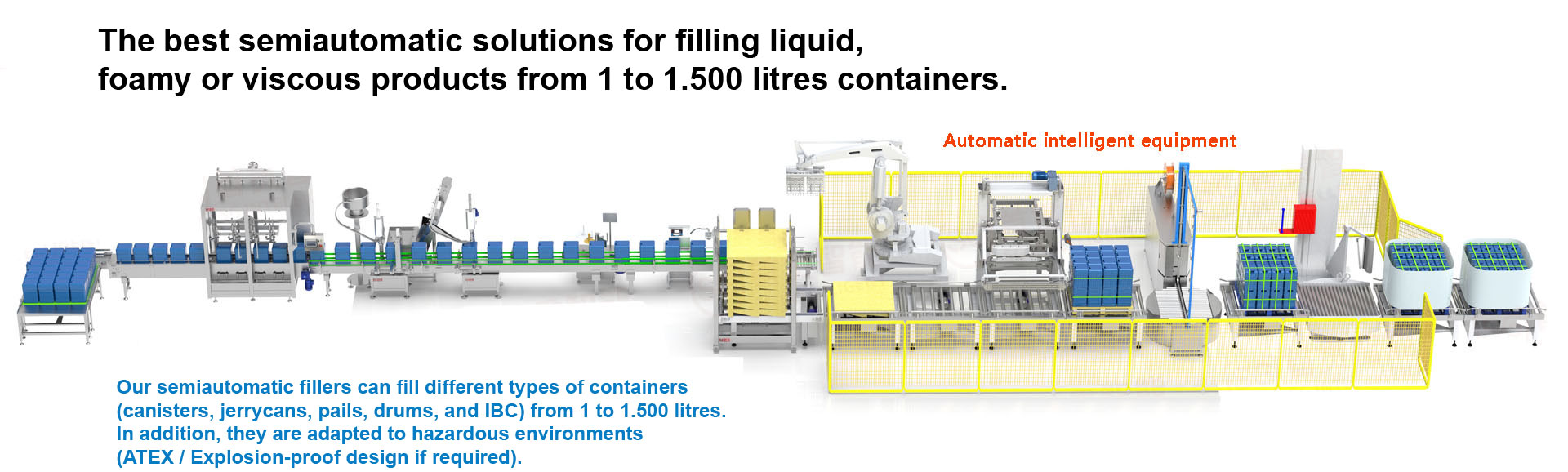

200L Semi Auto Thinner Explosion-Proof Drum Filler Machine[2025-04-23]

-

200L Explosion Proof Automatic Corrosive Glues Drum Filling Machine[2025-04-03]

-

Weighing Filling Machine - 200KG Putty Filling System (1-to-1 Customized Filling Equipment Service)[2025-05-17]