.Industrial-Grade 10L Hopper for Yogurt and Juice Manufacturing

Industrial-Grade 10L Hopper for Yogurt and Juice Manufacturing

Overview:

The 10L Industrial Hopper is a heavy-duty, precision-engineered solution designed for high-efficiency manufacturing of yogurt, juice, and other dairy or beverage products. Built to withstand the demands of commercial and industrial environments, it combines robust construction, hygienic design, and advanced features for seamless integration into production lines. Ideal for small to medium-scale operations, it ensures consistency, safety, and versatility in food processing.

Key Features:

Robust Construction:

304 Stainless Steel金彩汇: Corrosion-resistant, durable, and easy to clean. Suitable for high-temperature pasteurization and fermentation.

High-Density Food-Grade Plastic: Lightweight, impact-resistant, and cost-effective. Ideal for cold storage and juice processing.

Material Options:

Thickness: Commercial-grade walls (1.2–1.5mm stainless steel or reinforced plastic) for structural integrity.

Hygienic Design:

Smooth Interior Surfaces: Eliminates dead zones and prevents bacterial growth.

Rounded Corners: Minimizes contamination risks and facilitates thorough cleaning.

FDA-Approved Materials: Ensures compliance with food safety regulations (e.g., NSF, USDA).

Optimal Capacity:

10-Liter Capacity金彩汇: Perfect for small to medium batches, reducing waste and maximizing efficiency.

Graduated Markings金彩汇: Precise volume indicators for accurate ingredient measurement.

Versatility:

Yogurt Fermentation: Temperature-controlled environment for consistent culture growth.

Juice Processing: Mixing, storage, and transfer of juices while preserving freshness.

Dairy Products金彩汇: Kefir, sour cream, cheese-making, and more.

Broths & Sauces: Prepping and storing liquid bases in commercial kitchens.

Craft Beverages: Kombucha, infused drinks, and small-batch juice production.

Industrial-Grade Features:

Wide Mouth Opening: Easy access for stirring, cleaning, and adding ingredients.

Airtight Lid: Secure seal with silicone gasket to prevent contamination during fermentation or storage.

Mounting Brackets: For integration into production lines or equipment setups.

Handles or Lifting Eyes: Ergonomic grips or reinforced handles for safe transport.

Temperature Resistance:

Stainless Steel: Withstands temperatures from -40°C to 150°C (suitable for pasteurization, fermentation, and refrigeration).

Plastic: Temperature range of -20°C to 80°C (ideal for cold storage and juice processing).

Customization Options:

Agitation Systems: Optional stirrers or impellers for uniform mixing.

Thermometer Ports金彩汇: Integrated ports for temperature monitoring during fermentation.

Valves & Spouts: Controlled dispensing for precise pouring and transfer.

Insulated Covers: For maintaining consistent temperatures during fermentation.

Applications:

Yogurt Production金彩汇: Fermentation vessel for consistent texture and flavor.

Juice Manufacturing: Mixing, storage, and transfer of juices while preserving freshness.

Dairy Processing: Cultured dairy products like kefir, sour cream, and cheese.

Broths & Sauces: Prepping and storing liquid bases in commercial kitchens.

Craft Beverages: Kombucha, infused drinks, and small-batch juice production.

Why Choose This Hopper?

Efficiency金彩汇: Streamlined workflow with a multipurpose tool that reduces the need for multiple containers.

Durability金彩汇: Built to withstand heavy use in industrial settings, ensuring long-term reliability.

Compliance金彩汇: Certified materials and designs meet global food safety standards (FDA, NSF, USDA).

Cost-Effective: Affordable solution for small to medium-scale operations without compromising quality.

Optional Accessories:

Insulated Covers金彩汇: Maintain optimal temperatures during fermentation or storage.

Peristaltic Pumps金彩汇: Seamless integration into production lines for controlled dispensing.

Digital Thermometers: Precise temperature monitoring for fermentation processes.

Agitation Systems金彩汇: Stirrers or impellers for uniform mixing of ingredients.

Transfer Hoses: Food-grade hoses for safe and efficient product transfer.

Maintenance Tips:

Cleaning:

Thoroughly clean after each use with food-safe sanitizers (e.g., bleach solutions, hydrogen peroxide).

金彩汇Use non-abrasive brushes or sponges to preserve the hopper’s surface.

Sanitization:

金彩汇Regularly sanitize with hot water and food-grade sanitizing agents.

Storage:

金彩汇Store in a dry, cool place away from direct sunlight when not in use.

Inspection:

金彩汇Periodically check for signs of wear, corrosion, or damage to ensure optimal performance.

Ideal For:

Industrial dairies and juice manufacturers.

金彩汇Artisanal yogurt and cheese producers.

金彩汇Juice bars, smoothie shops, and craft beverage creators.

Commercial kitchens and food processing facilities.

Invest in the 10L Industrial Hopper for a reliable, high-performance solution that enhances your yogurt and juice manufacturing efficiency!

Immediate Order:

Website: http://zonghengdazong.com/product/drumfillingmachines-en.html

Alibaba:

金彩汇China Manufacturing Co Ltd.:

-

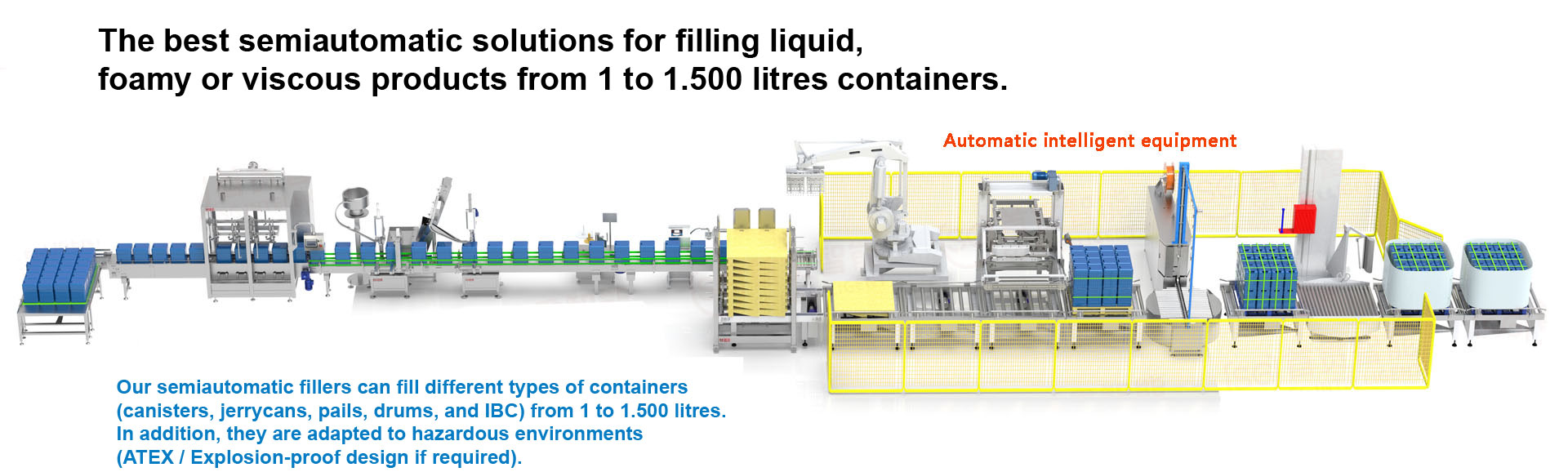

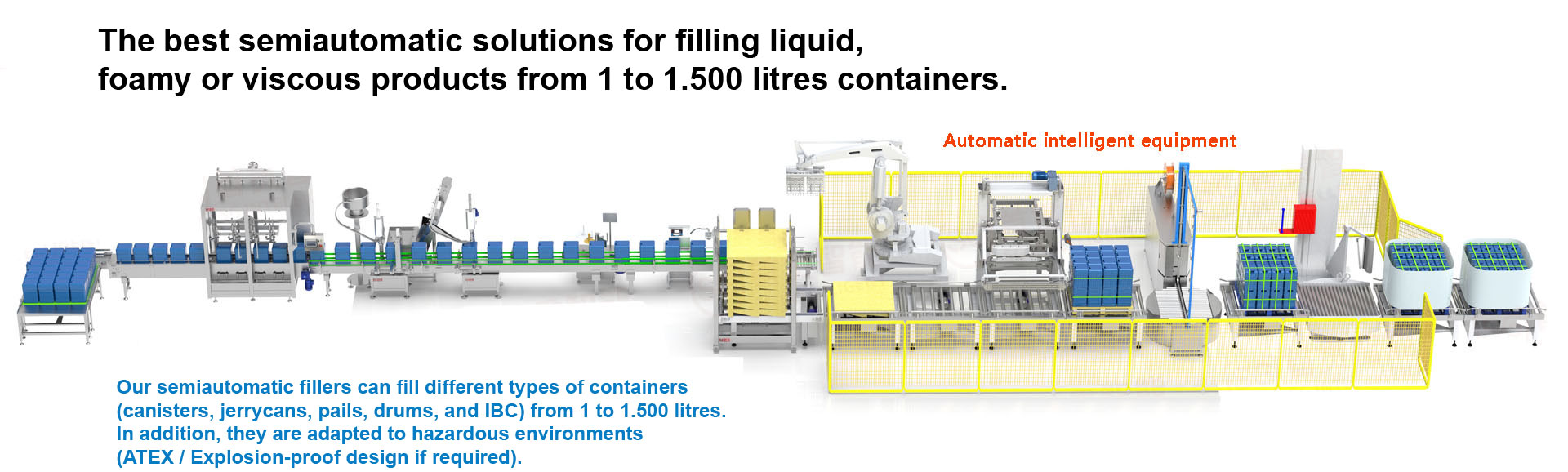

5 Litre High Viscosity Foamy Liquids Filling Machine for Liquid Soap[2025-05-21]

-

Ink Solvent/Fertilizer Power Conveyor Filling Machine[2025-07-05]

-

Fully Automatic Upper Lid and Capping Filling Machine for 25L 30L[2025-05-30]

-

High Efficiency Filling Machines 5 Gallon Pail Filling Equipment for Chemical Materials[2025-04-29]