50kg Building Industrial Used Cement Bagging Packing Machine

50kg Cement Bagging Packing Machine for Industrial Use

Overview

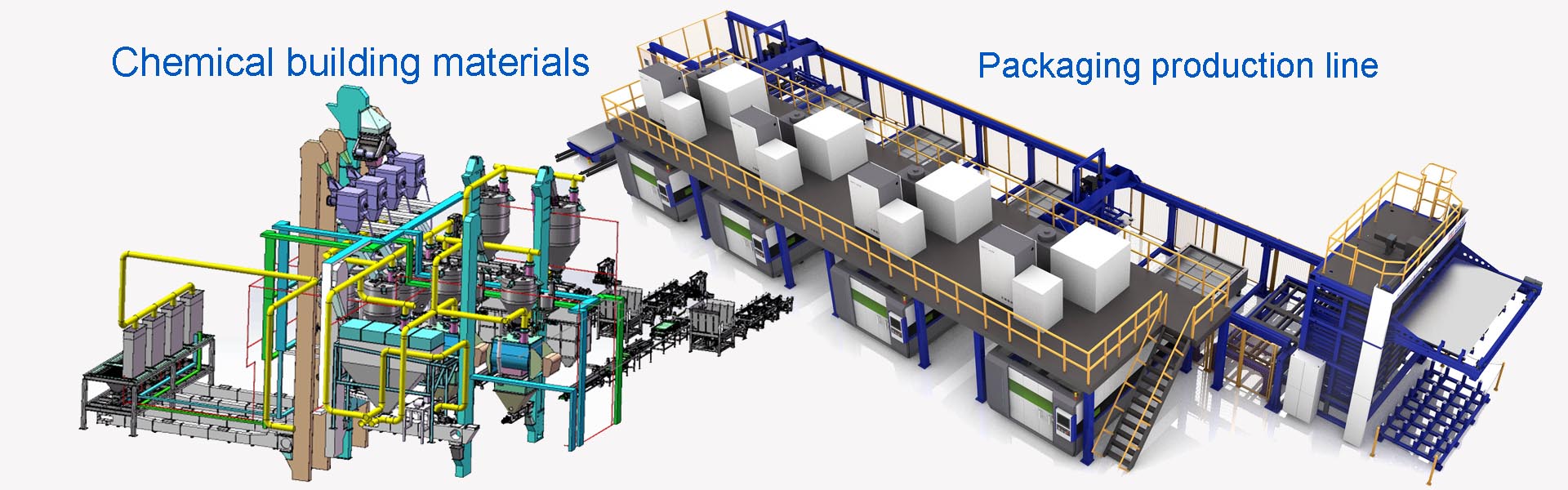

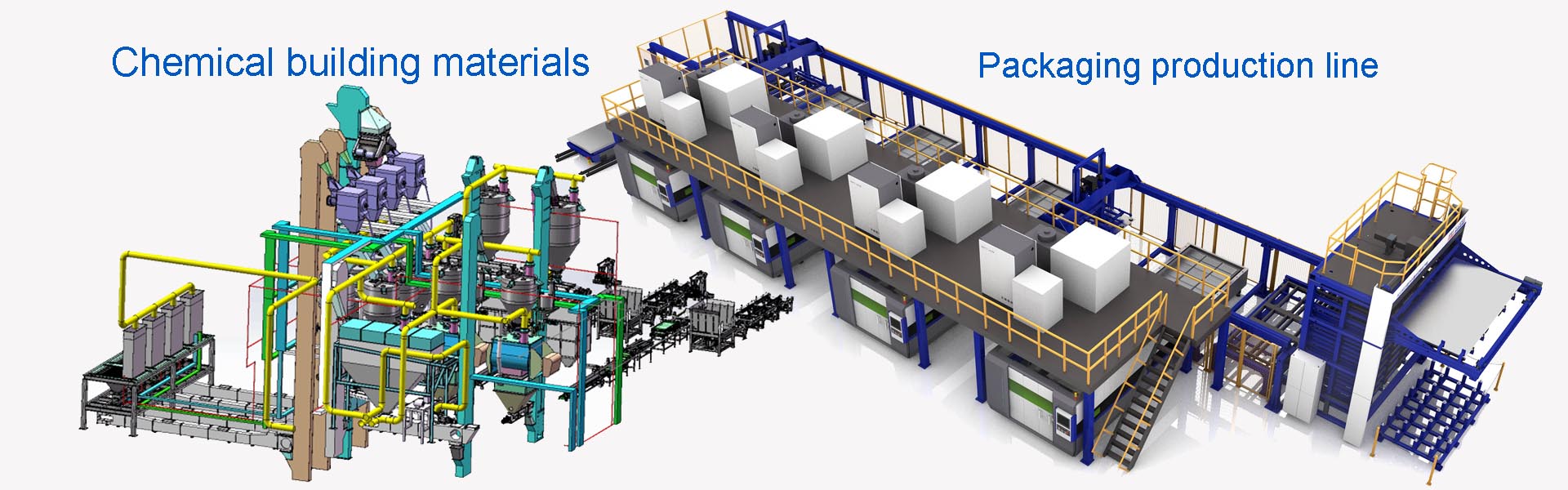

The 50kg Cement Bagging Packing Machine is a heavy-duty, industrial-grade solution designed for efficient and precise packaging of cement, sand, dry mixes, and other free-flowing materials. With a 50kg capacity per bag, it is ideal for construction, mining, and bulk material handling applications. This machine combines automated weighing, filling, and sealing金彩汇 to ensure high throughput, accuracy, and contamination control.

Key Features

High-Speed Automation

Throughput: Up to 200–300 bags/hour金彩汇 (depending on material flow and bag type).

Fully Automatic Operation: From filling to sealing, with minimal manual intervention.

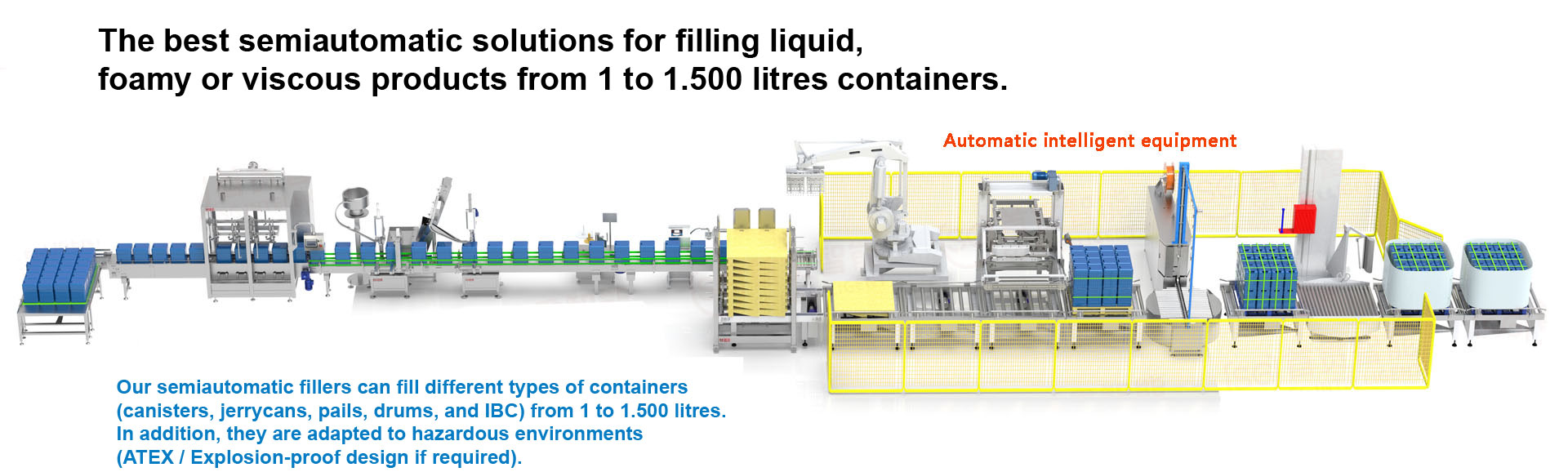

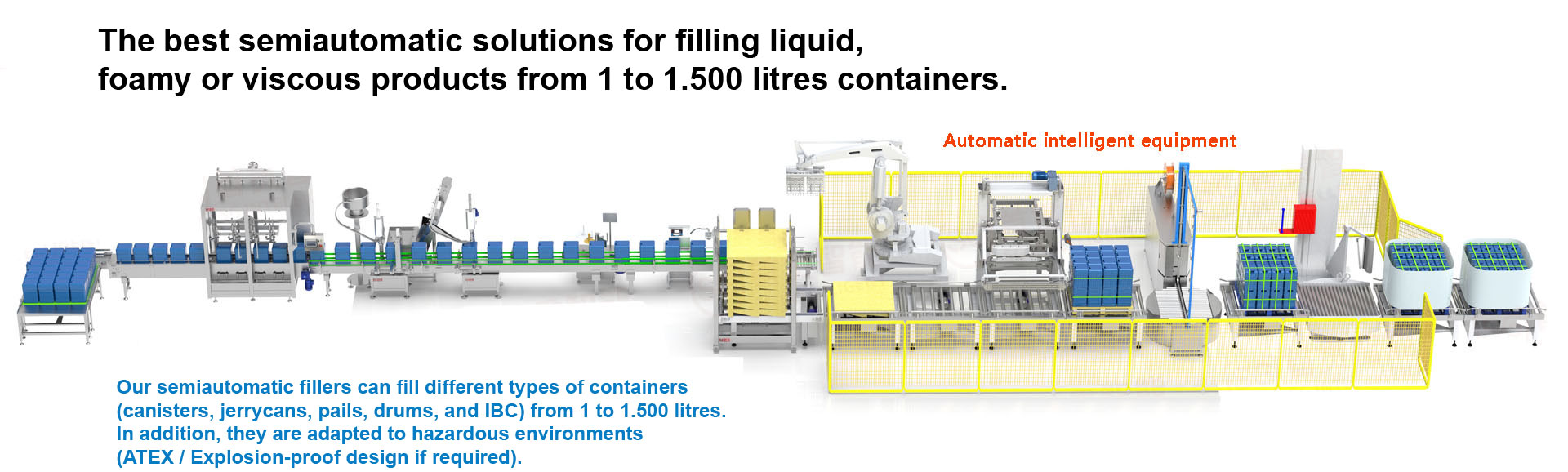

Integrated Conveyor System: Automatic bag feeding, positioning, and discharge.

Precision Weighing & Filling

Load Cell Accuracy: ±0.2% accuracy for consistent 50kg fill weights.

Weighing Module: Real-time weight monitoring and adjustment during filling.

Vibration-Assisted Feeding: Ensures smooth flow of dense or cohesive materials like cement and sand.

Material Compatibility

Dry, Free-Flowing Materials:金彩汇 Suitable for cement, sand, dry mixes, chemical powders, and more.

Customizable Hopper: Stainless steel hopper with adjustable gates for controlled material flow.

Dust Control: Integrated dust extraction system to minimize environmental contamination.

Bag Handling & Sealing

Bag Type Compatibility: Works with valve bags, open-mouth bags, or jumbo bags (customizable).

Automated Sealing:金彩汇 Heat-sealing or ultrasonic sealing module for secure bag closure.

Bag Printing (Optional): Inkjet or thermal printer for batch numbers, expiration dates, or branding.

Robust Construction & Safety

Stainless Steel Frame: Corrosion-resistant 304/316L stainless steel for durability.

ATEX Compliance:金彩汇 Suitable for hazardous environments (optional).

Emergency Stop & Safety Sensors: Prevents jams and operator injury.

User-Friendly Interface

HMI Touchscreen: Easy setup for fill weights, speed, and diagnostics.

Pre-Programmed Recipes:金彩汇 Store settings for different products or bag sizes.

Remote Monitoring:金彩汇 IoT-enabled connectivity for real-time data tracking and troubleshooting.

Technical Specifications

Filling Range:金彩汇 1–50kg (adjustable in 0.1kg increments).

Accuracy:金彩汇 ±0.2% of target weight.

Material Compatibility:金彩汇 Dry, free-flowing powders and granular materials.

Power Requirements: 220V/50Hz or 110V/60Hz (customizable).

Safety Rating:金彩汇 IP65 (dust and water resistant).

Dimensions: Customizable based on production line layout.

Operation Steps

Bag Placement:金彩汇 Automatically feeds bags onto the weighing platform via conveyor.

Weighing & Filling: The hopper dispenses material while load cells monitor weight in real time.

Sealing:金彩汇 Once the target weight is reached, the bag is sealed automatically.

Discharge:金彩汇 Filled and sealed bags are transported to downstream processes (e.g., palletizing).

Cleanup:金彩汇 Dust extraction and automated cleaning systems minimize material residue.

Applications

Cement & Sand:金彩汇 Perfect for construction materials requiring precise 50kg bagging.

Dry Mixes: Ideal for packaging concrete, mortar, and other construction blends.

Chemicals & Fertilizers:金彩汇 Safe handling of corrosive or dusty powders.

Mining & Quarrying:金彩汇 Efficient bagging of aggregates, gravel, and other bulk materials.

Industrial Powders:金彩汇 Packaging of abrasive or hygroscopic materials.

Benefits

Efficiency: High-speed operation reduces labor costs and increases productivity.

Accuracy:金彩汇 ±0.2% precision ensures compliance with industry standards and reduces waste.

Versatility: Customizable for different materials, bag types, and production needs.

Low Maintenance: Robust design and automated cleaning systems minimize downtime.

Safety: Dust control and safety sensors protect operators and equipment.

Scalability:金彩汇 Easily integrates with larger production lines or additional processes (e.g., palletizing).

Why Choose This Machine?

This 50kg cement bagging machine is built for industrial-grade reliability, with a focus on accuracy, speed, and safety. It is ideal for high-volume operations in construction, mining, and manufacturing sectors. Contact us for a tailored quote or consultation!

Immediate Order:

Website: http://zonghengdazong.com/product/drumfillingmachines-en.html

Alibaba:

China Manufacturing Co Ltd.:

-

Heavy-Duty Auger Open Mouth Packaging Machine for Packaging Sugar/Salt/Pasta/Seeds[2025-07-05]

-

Fully Automatic Palletizing Machine Production Line[2025-06-09]

-

Automatic Clamping packaging machine Face Mask Freeze-Dried Powder packaging machine[2025-06-30]

-

Automatic Lid Opening packaging machine Equipment production factory[2025-07-02]