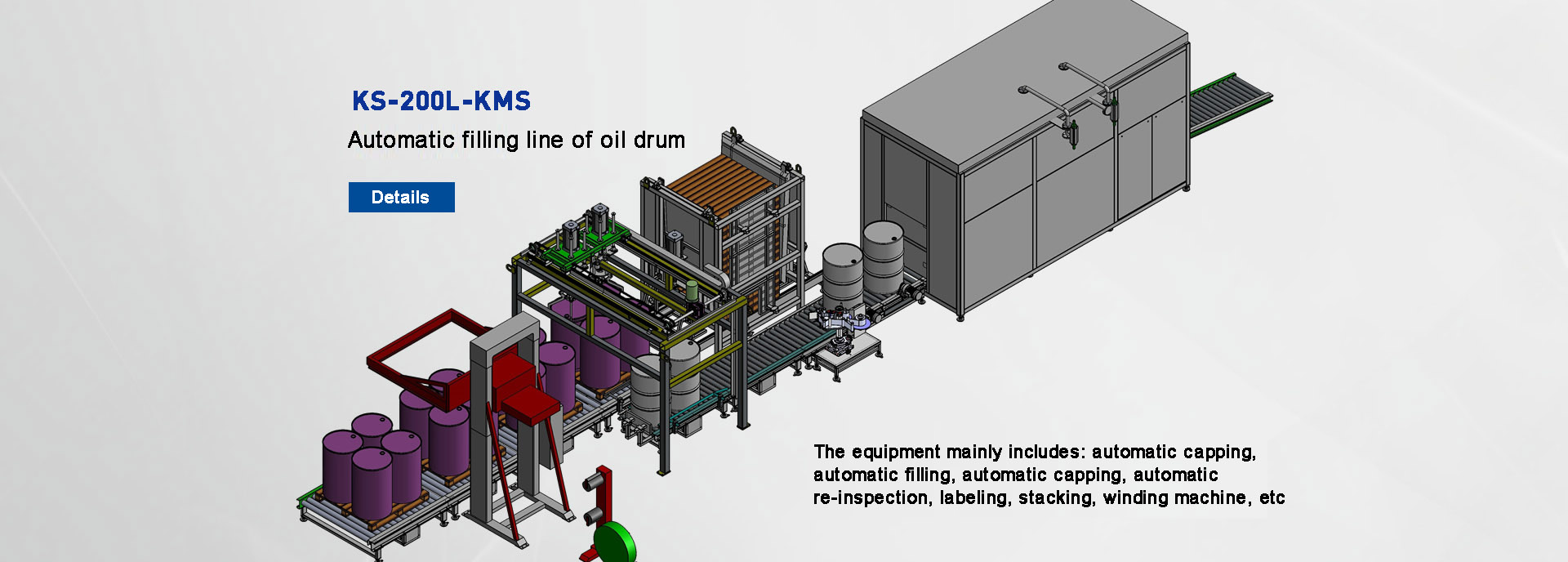

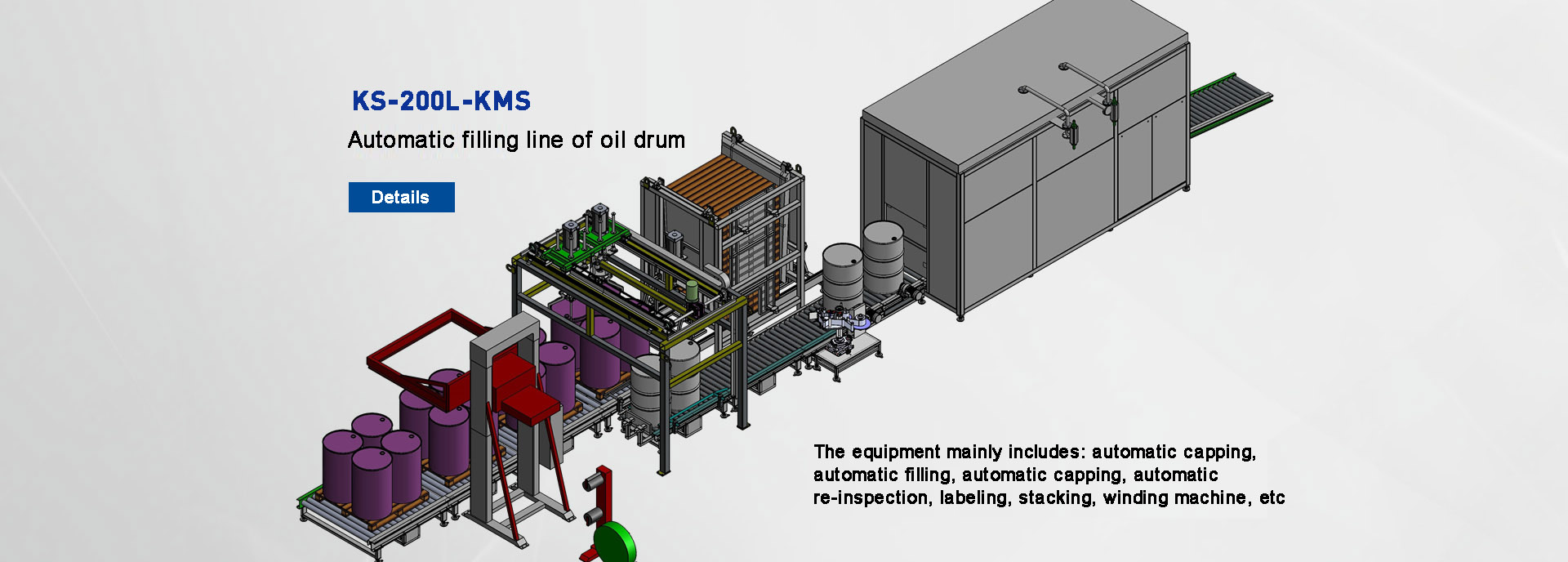

Chemical Solvent Liquid Filling Machine - 200L Liquid Filling Machine - Swing Arm Liquid Filling Machine

Chemical Solvent - 200L Liquid Filling Machine - Swing Arm Liquid Filling Machine

Our Company Specializes In:

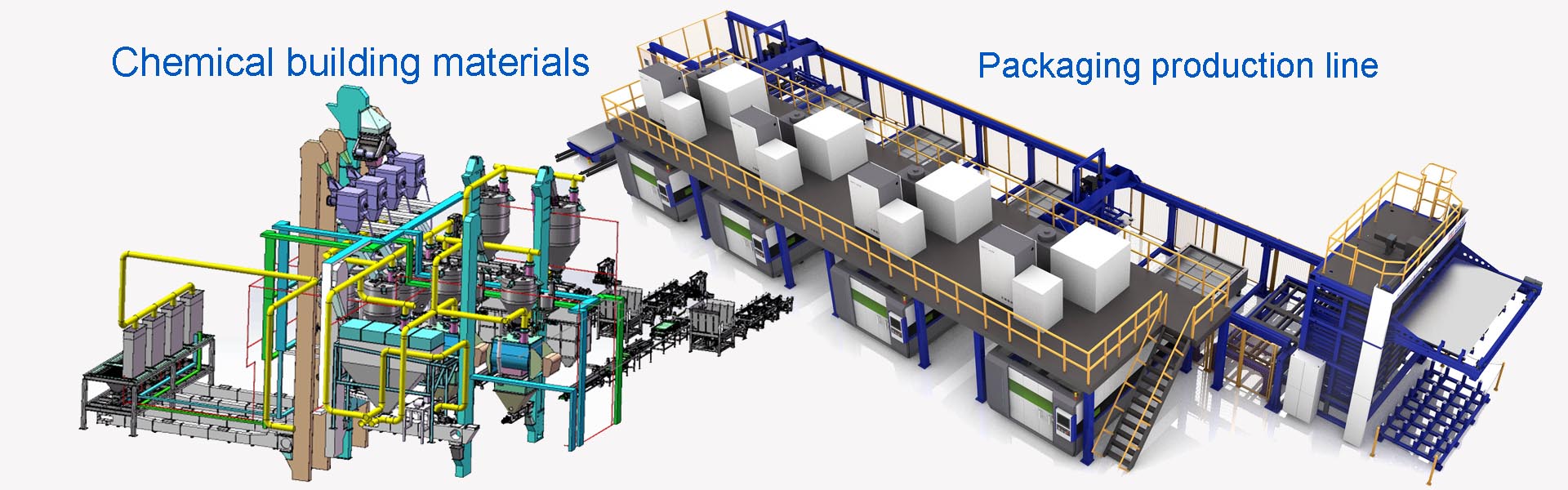

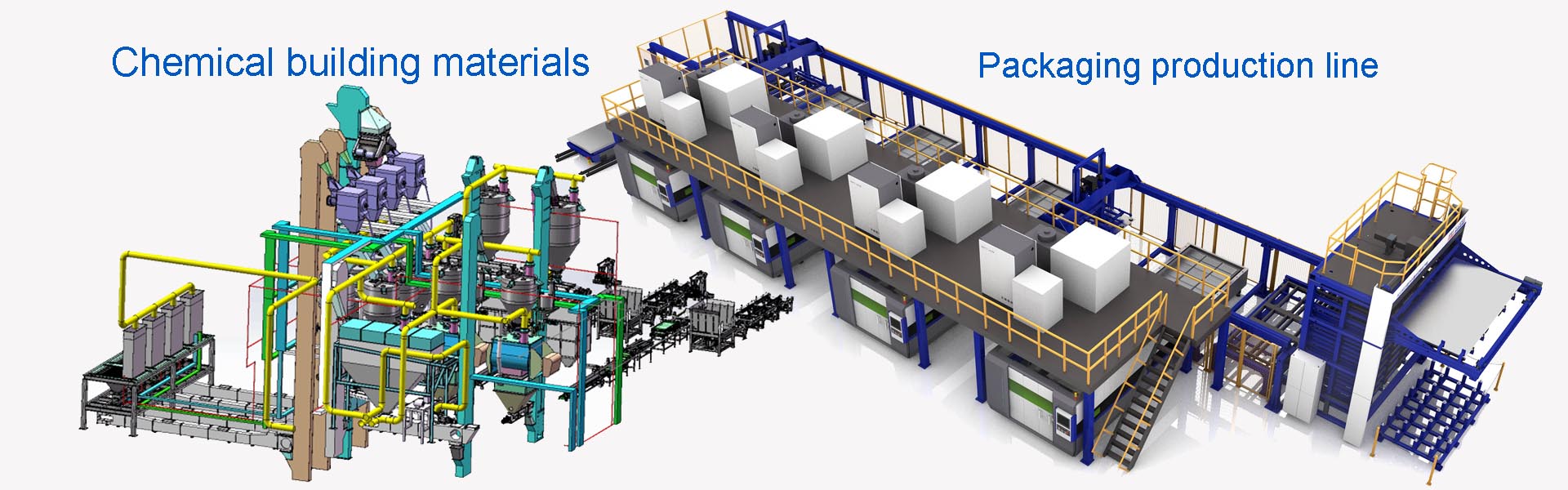

金彩汇A comprehensive range of packaging equipment, including:

金彩汇Fully automatic weighing liquid filling machines

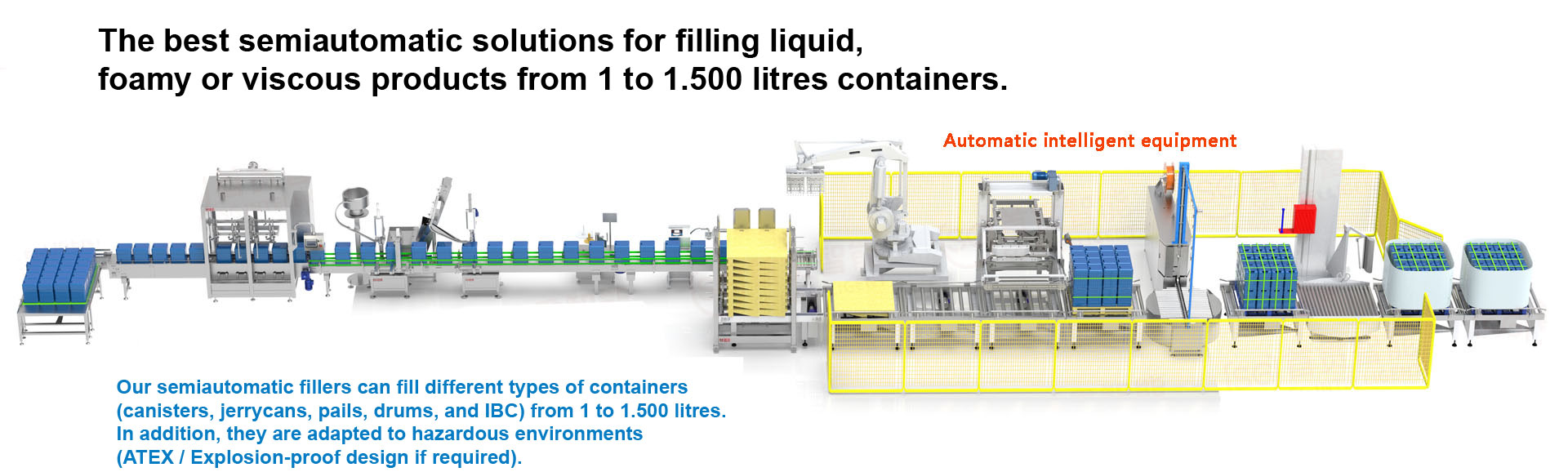

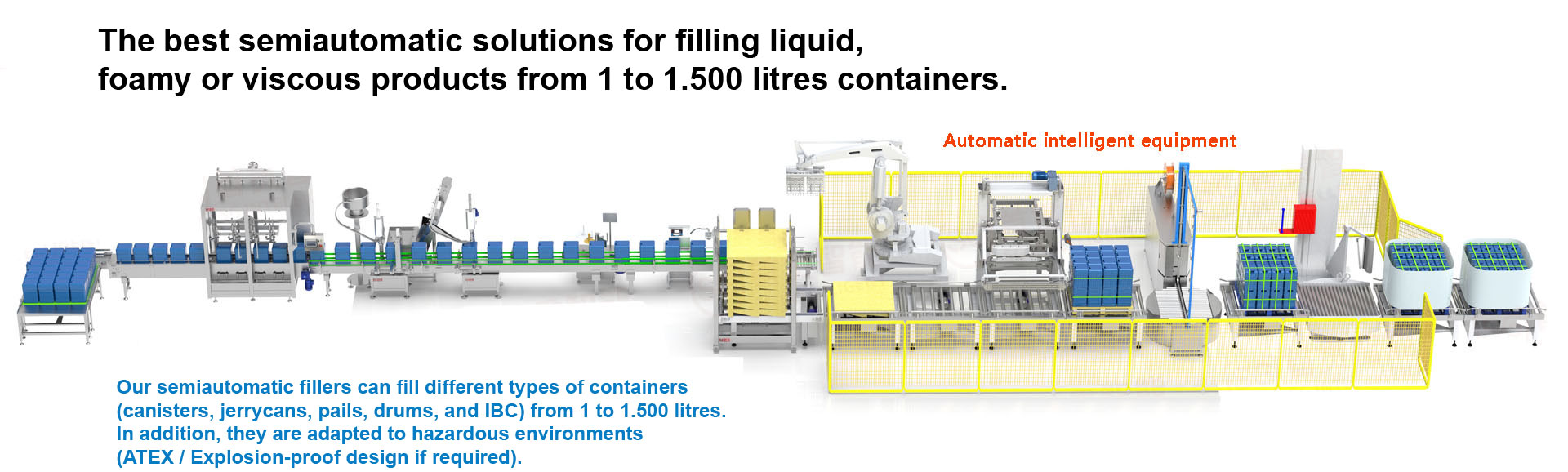

Semi-automatic liquid filling machines

金彩汇Automatic capping and screwing machines

Automatic lid feeding machines

Labeling conveyors and wrapping machines

Fully automatic packaging machines and palletizing production lines

金彩汇Palletizers and other complete filling/packaging solutions

Technical Parameters:

| Parameter | Details |

|---|---|

| Filling Range | 60-200kg |

| Filling Speed | 4-5 tons/hour (requires sufficient pipe diameter & good liquid flow) |

| Weighing Platform | 800×760mm |

| Suitable Barrel Height | ≤1000mm (customizable for varying heights) |

| Applicable Barrel Neck | ≥40mm (filling caliber adapts to barrel opening) |

| Division Value | 0.01kg |

| Filling Accuracy | 1-3‰FS |

| Compressed Air | 0.3-0.6MPa |

| Operating Environment | Temperature: -10°C to +45°C, Relative Humidity ≤90% |

| Power Supply | AC220V, 50Hz, 0.3Kw |

| Note | Material viscosity <20000cp; pre-filling pressure: 0.3±0.1MPa; flow >300L/Min |

Key Features:

Manual/Automatic Mode金彩汇: Flexible operation switching.

Precision Weighing金彩汇: Uses imported components for accuracy.

Quick Parameter Setup金彩汇: Intuitive shortcut keys for fast adjustments.

Multi-Recipe Storage金彩汇: Stores up to 10 formula configurations.

Dual-Speed Filling金彩汇: Adjustable fast/slow feeding rates.

Anti-Collision Design: Automatically retracts filling gun on impact.

Self-Correcting System: Enhances accuracy for subsequent fills.

Smooth Operation: Linear guide rails ensure effortless movement.

Vibration Damping: Locking mechanism minimizes errors from motion.

Diagnostic Alarms: Weighing errors and faults trigger instant alerts.

Automatic Taring: Compensates for variable container weights.

Corrosion Resistance金彩汇: 316 stainless steel for material contact; PTFE plug for harsh chemicals.

Production Tracking: Counts filled barrels and total weight automatically.

Explosion-Proof Option金彩汇: Suitable for hazardous environments (customizable).

Automated Capping金彩汇: Optional add-on for streamlined workflows.

Heating System: Optional insulation for temperature-sensitive materials.

Data Connectivity: Standard RS232/485 ports; optional industrial bus protocols.

Equipment Workflow:

Automatic decapping

Barrel cleaning and rinsing

Barrel feeding and positioning

金彩汇Sterilization and flushing

Precision filling

金彩汇Lid alignment, capping, and pressing

金彩汇Quality inspection (lamp check)

Heat-shrink film sealing

Final bagging and conveying

Applications:

Industries: Food processing, pharmaceuticals, chemicals.

Materials金彩汇: Liquids, solvents, oils, and low-viscosity chemicals.

After-Sales Service:

Service Booking金彩汇: Schedule via hotline for prompt assistance.

On-Site Support: Engineers dispatched within 24 hours for debugging/maintenance.

Comprehensive Repairs金彩汇: Swift resolution of equipment issues.

Post-Repair Inspection: Thorough testing and hidden-problem checks.

Transparent Reporting金彩汇: Detailed maintenance records and pricing.

Follow-Up: Callback within 3 working days post-service.