25L Polyurethane Filling Machine - Explosion-Proof Automated Filling & Weighing Solution

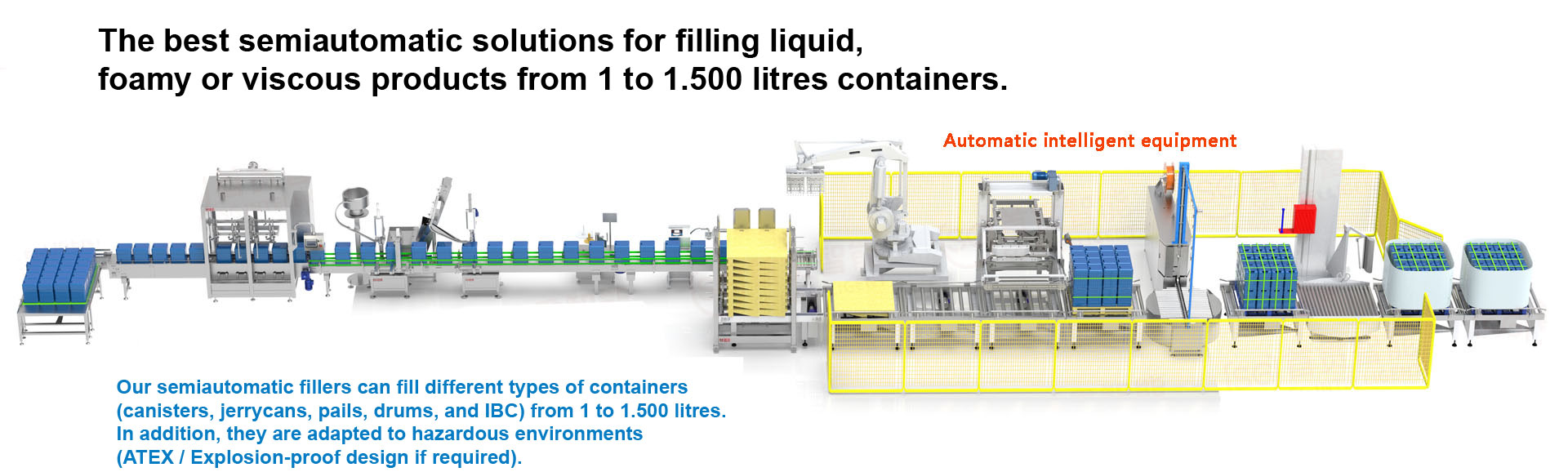

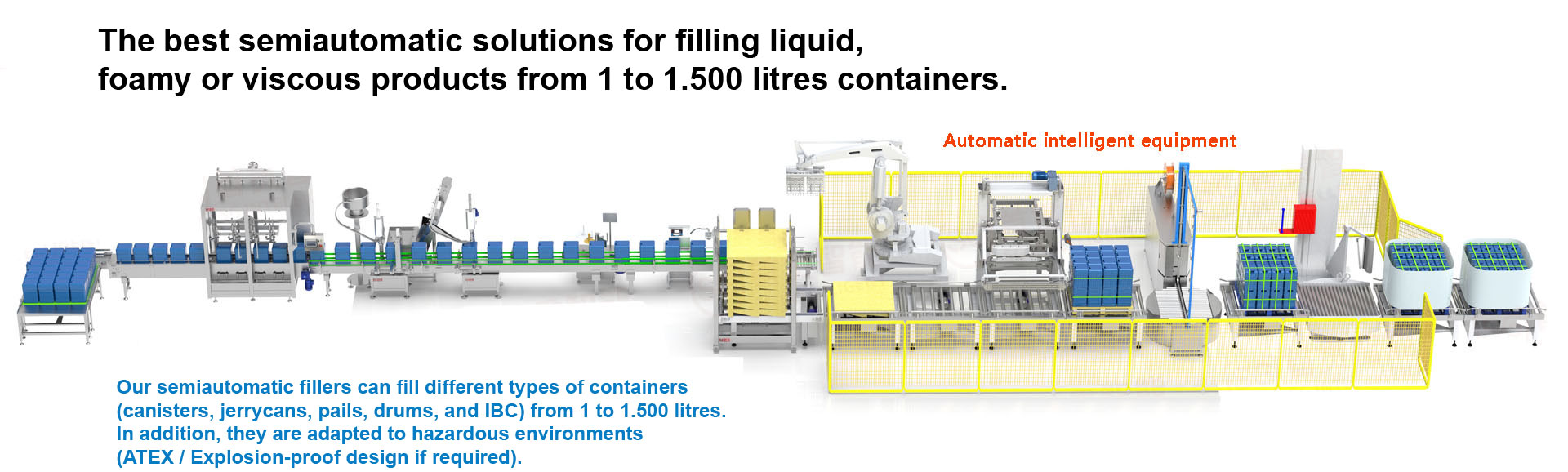

Shanghai Guangzhi Automation Equipment Co., Ltd. specializes in providing professional automated packaging equipment, including dyeing auxiliaries filling machines, adhesive filling machines, semi-automatic filling machines, corrosion-resistant filling machines, and automatic filling machines. These systems are widely used for filling and packaging liquids, powders, pastes, and other materials. We adhere to the philosophy of "market-oriented, innovation-driven, and quality-guaranteed"金彩汇 to continuously improve our products and services.

25L Polyurethane Filling Machine | Explosion-Proof Automated Filling & Weighing Solution

Technical Parameters:

Filling Range: 10-30kg

Max. Weighing Capacity: 30kg

Min. Sensitivity: 10g

Filling Accuracy: ≤0.1%

Filling Speed: 180-240 drums/hour

Container Size:金彩汇 ≤φ400×H500mm

Nozzle Material: SUS304/316

Power Supply:金彩汇 AC220V/50Hz

Air Supply:金彩汇 0.5MPa

Optional Configurations: Feeding pump, capping machine

Explosion-Proof Models: V5-30AE/BE/CE

Operating Temperature:金彩汇 -10℃~50℃

Key Features:

High automation, easy operation, stable performance – Reduces costs and improves efficiency.

Independent control system金彩汇 – Each unit operates with a digital display for parameter adjustment, enabling standardized production.

Quick linkage/separation – Fast adjustment for coordinated production processes.

Multi-size container compatibility – Adaptable to various drum specifications.

Smooth production line operation – Customizable configurations based on user requirements.

Operation Process:

Manual drum placement → Manual start → Automatic feeding (pump & valves) → Fast/slow filling control → Manual capping → Drum transfer via stainless steel .

Applications:

Suitable for resins, additives, oils, paints, and other chemical materials.

After-Sales Service:

User manual & quality assurance documents provided.

Original component details & spare parts list included.

Standard operation, maintenance, and GMP validation documents supplied.

Free training covering:

Equipment functions, structure, and performance.

Installation, operation, and performance verification.

Maintenance, inspection, and troubleshooting.

Safety measures & emergency protocols.

1-year warranty – Cost-priced spare parts, on-site service within 24 hours.

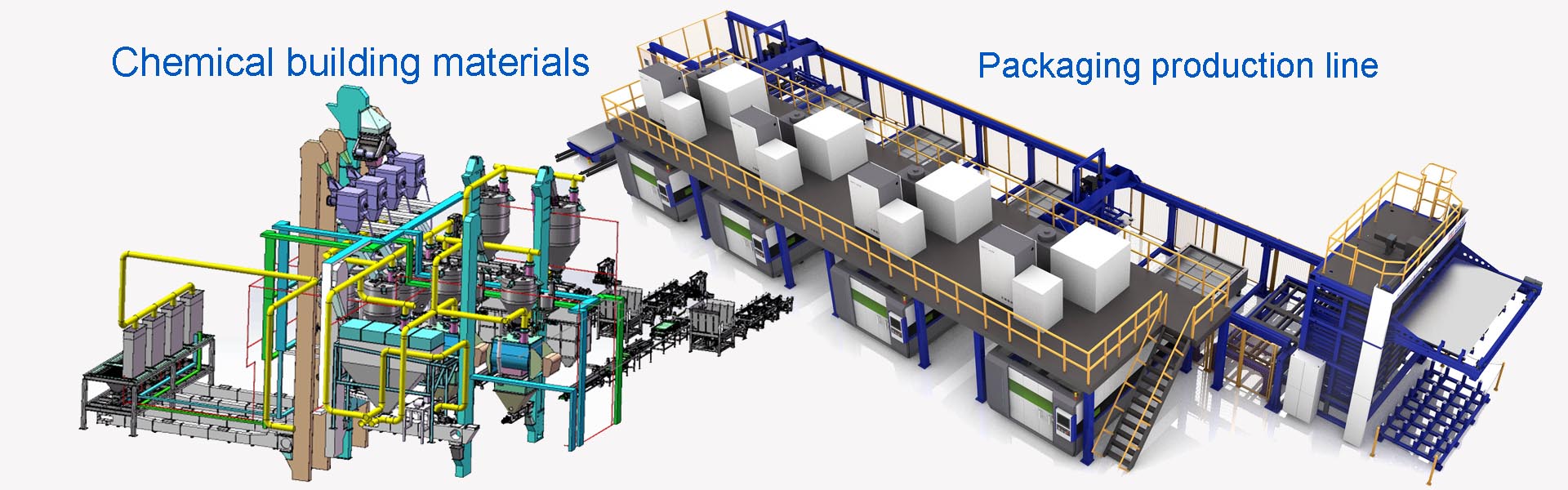

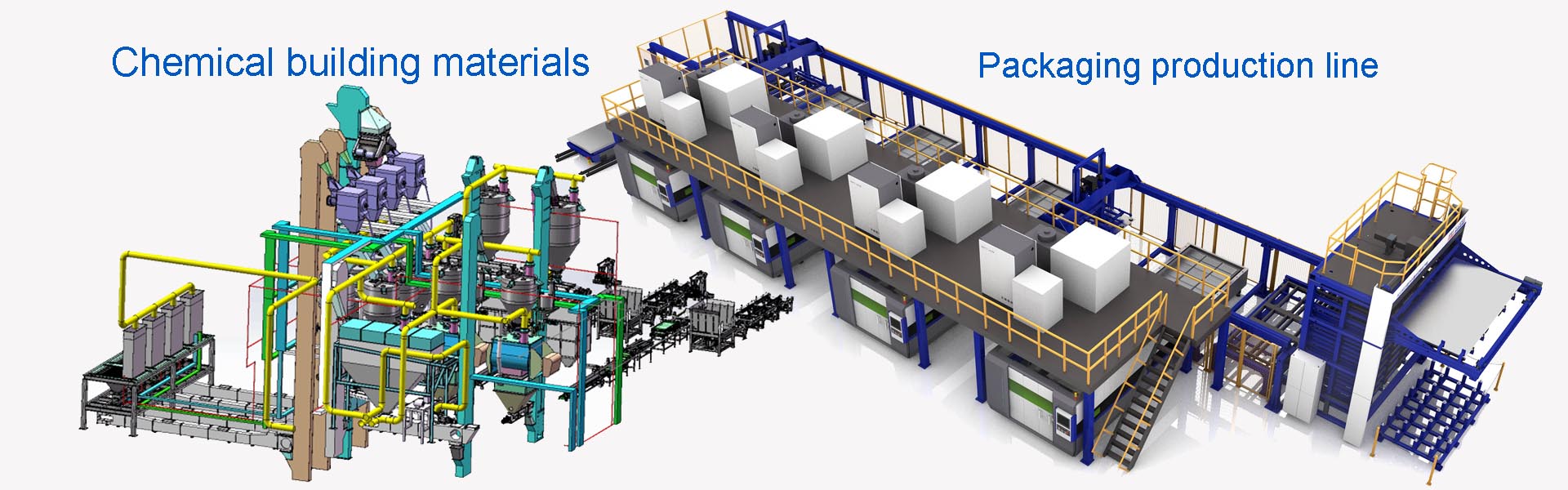

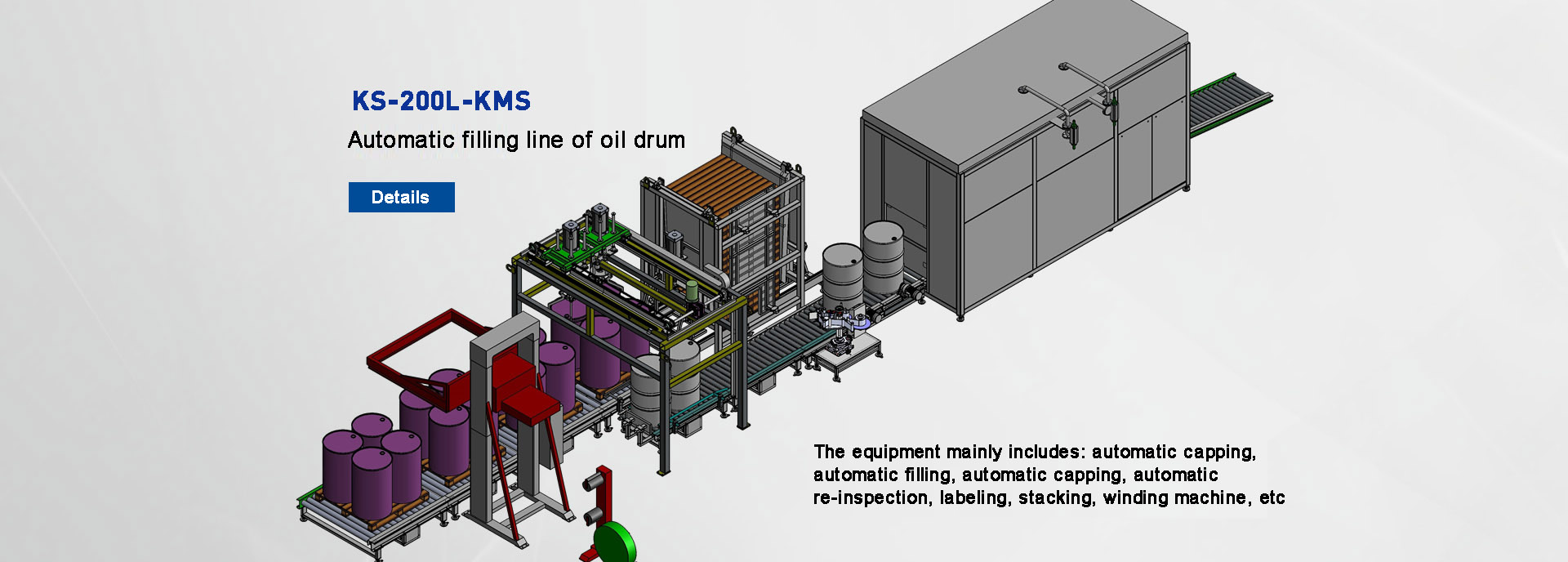

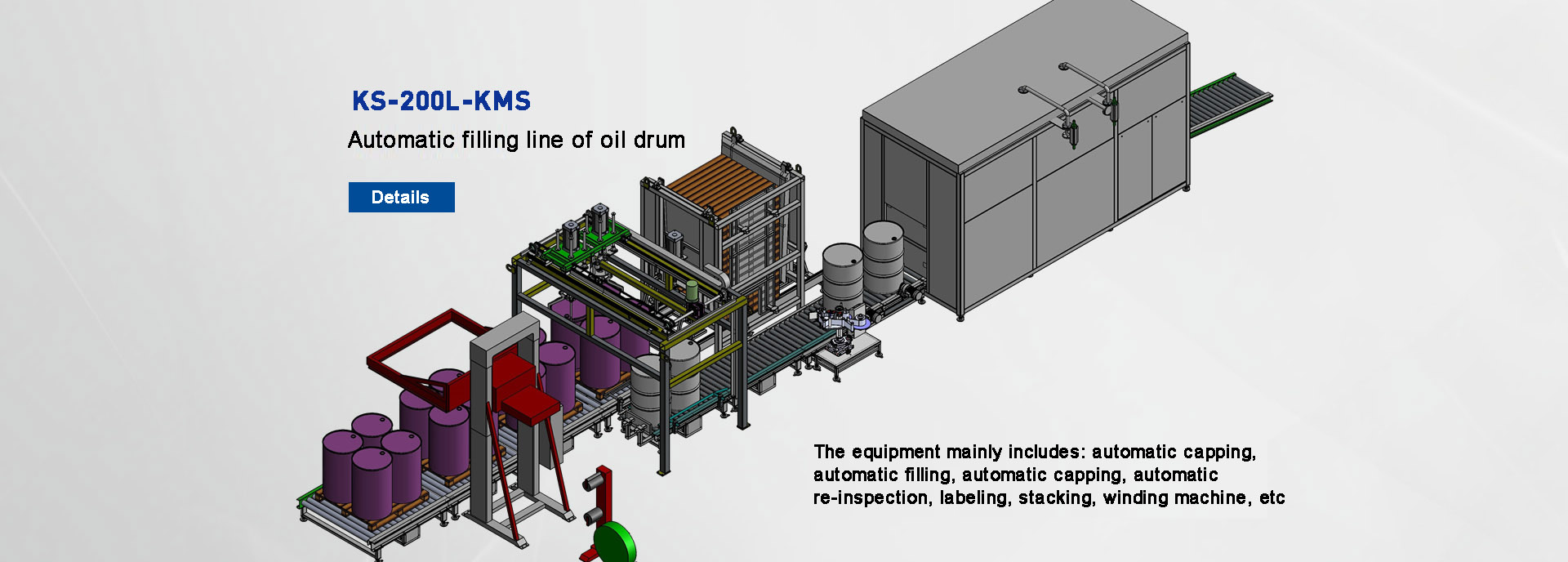

Related Equipment:

18L Putty Capping Machine金彩汇 | Auto-Labeling & Capping

25kg Petrochemical Packing Machine金彩汇 | Submersible Explosion-Proof Model

20kg Grease Filling Machine | Dual-Station Rotary Arm Filler

16L | High-Viscosity Filling System

20L Multicolor Paint Packing Machine | Immersion-Type Packer

For inquiries, contact us today!